Strategic’s 100% Recyclable RMR Helmet Wins Australian Good Design Award

We are honored to announce that Strategic Sports innovative, sustainable and 100% recycled/recyclable RMR model helmet has been recognized with yet another prestigious award, this time the Australian Good Design Award in the Product Design category. This accolade highlights its innovative approach specifically to sustainable design and environmental impact. The RMR has also won the 2024 German Design Award earlier this year.

Since 1958, the Australian Good Design Awards have celebrated outstanding design and innovation across 12 design disciplines. The 2024 awards featured over 32 categories, judged by a panel of more than 80 global experts, including designers, engineers, and industry leaders Judges focused on three main criteria: Good Design, Design Innovation, and Design Impact. The RMR helmet stands out for its commitment to sustainability and effectiveness, reinforcing the important role of design in creating a better future for our planet.

“We’re truly honored to receive a Good Design Award for our efforts on the sustainable, 100% recycled and recyclable RMR,” said Norman Cheng, Managing Director of Strategic Sports LTD. “However, our focus on sustainable design goes beyond accolades; we believe it's crucial for manufacturers to actively contribute to sustainability and combat climate change whenever possible,” Cheng added.

Take A Closer Look at the Award-Winning, Incredibly Recyclable RMR

The RMR is the first helmet engineered and manufactured with sustainability as a top priority. Produced at Strategic Sports low carbon factories using their Biodome™ reclaimed and recycled materials, the RMR features adhesive-free construction to simplify disassembly for recycling post-life, while still exceeding global safety standards.

Design Challenges, Design Solutions

Like any helmet, the RMR is designed to prevent injury in the event of impact. Traditional helmet materials and construction methods have centered around this critical energy management element and pricing scaled to meet end consumer needs, which unfortunately has usually involved a plethora of non-recycled, non-reclaimed materials and processes. For the RMR the Design Challenge was clear: make a helmet that’s just as safe, while focusing on reclaimed and recycled materials and new assembly methods to facilitate post-consumer materials reclamation while retaining an attractive, comfortable design at an acceptable cost.

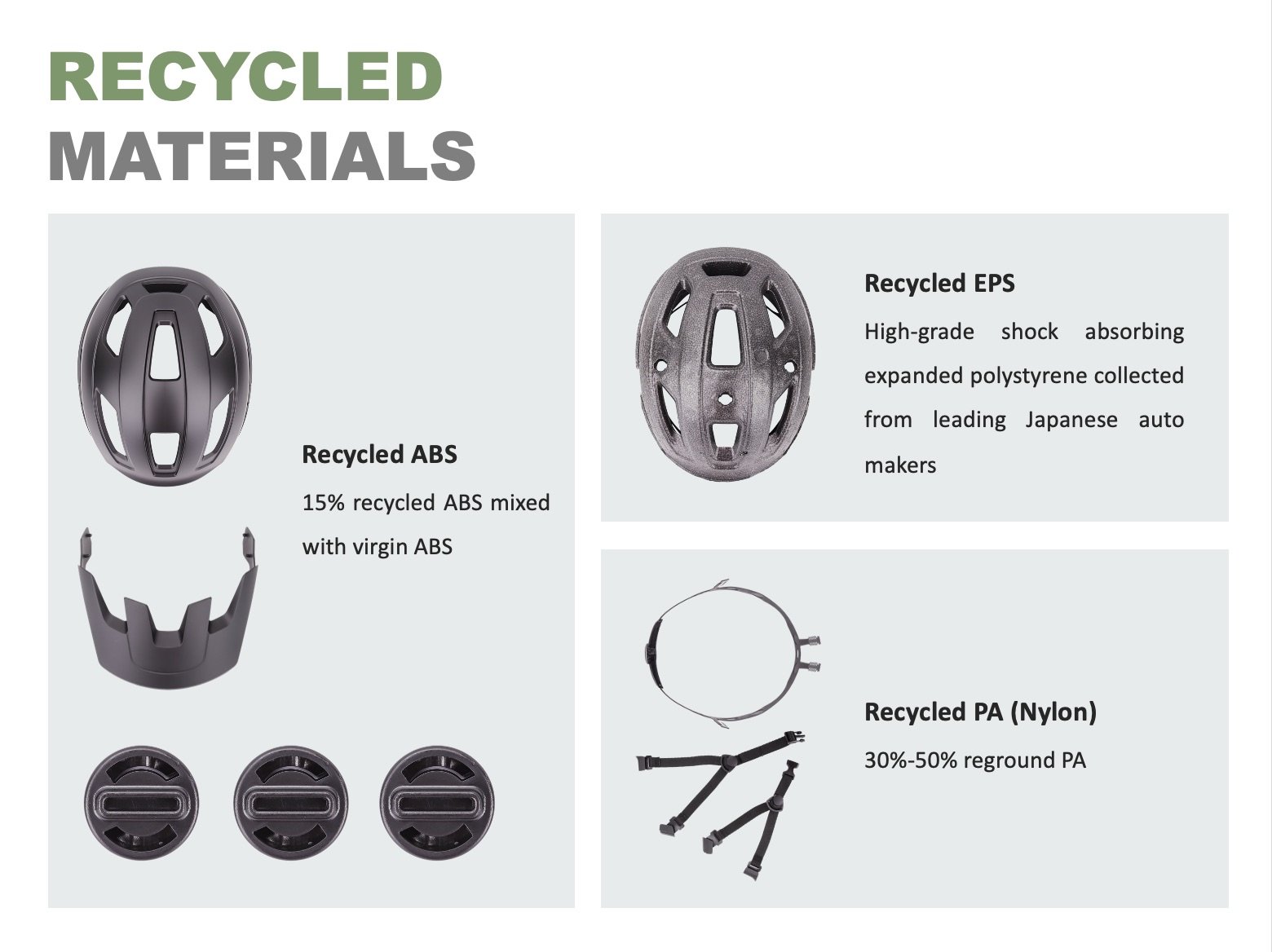

The RMR’s recycled Biodome™ materials story starts with sterile, top-quality EPS reclaimed from partners in the Japanese automotive industry. Recycled ABS plastic and PA nylon is mixed with a percentage of virgin material to meet the strength needs for small parts, and everything comes packaged in FSC certified boxes and compostable polybags, with recycled paper manuals using soy-based ink. A helmet’s impact performance is tied to how it is designed and assembled, traditionally using adhesives which impede recycling. The biggest challenge was the development of a new mechanical interface to securely assemble the RMR and pass rigorous safety tests.

Reducing Global Impact

Strategic Sports places considerable focus on sustainable manufacturing processes and products, and the work accomplished with the RMR, including Biodome™ reclaimed and recycled materials and new adhesive-free assembly processes to facilitate and simplify post-consumer recycling will allow similar product offerings to be made available to Strategic’s helmet customers worldwide. Recycled products have often come at an increased cost and reduced performance, but with the RMR Strategic has proven that doesn’t have to be the case. Strategic believes the RMR could be the beginning of a dramatic reduction in the environmental impact of the helmet industry worldwide.

Design Innovation

The design innovation of the RMR can potentially change how designers consider certain aspects of projects. When sustainability and environmentally responsible manufacturing and products are discussed, it’s often limited to materials choices. While it is certainly important to use reclaimed, sustainable, and recyclable materials throughout, the full potential benefit of sustainability is lost if the product’s end-of-life is not also considered. Glues are fast and affordable methods to assemble complex products, but they can render a well-intended recycled product to be far less sustainable than it might have been.

The RMR represents a shift in the philosophy of design and assembly of complex products. Helmets, which are designed as life-saving devices, must meet rigorous safety standards and the RMR’s non-adhesive assembly exceeds those safety tests while proving that by considering disassembly and recycling at the start of a project can result in a product with an entirely sustainable life cycle. And if this practice can be applied to something as complex and safety focused as a bicycle helmet, then it’s reasonable to hope that we’ll see more designers consider similar methodology in their own work.

This is Just the Beginning

The RMR is impactful in that it proves that quality sporting helmets can be manufactured in a sustainable manner, which historically has not been the case.

The materials and technology found in the RMR can easily be applied to other types of bicycle helmets catering to different types of riders, and potentially also to motorcycle, snow sports, equestrian and industrial helmets, ultimately reducing the carbon footprint of safety helmets overall.

Simply put: if you were to purchase a helmet, knowing that it could be sustainable and recyclable, wouldn’t you want it to be? And if you were a company developing a new helmet, knowing this technology exists, why wouldn’t you incorporate this into your project?